Revolving arm automatically loads / unloads material.

Revolving arm automatically loads / unloads material.

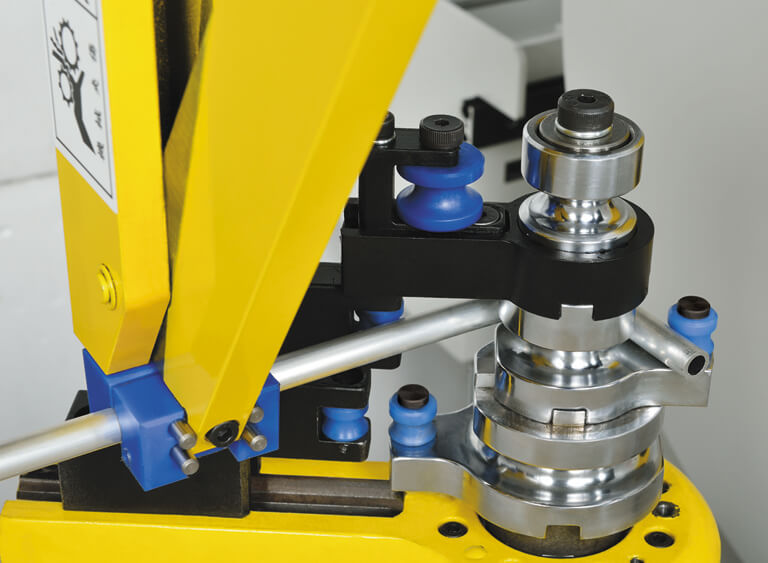

Reversible mode; performs stretch bending or roll bending processing.

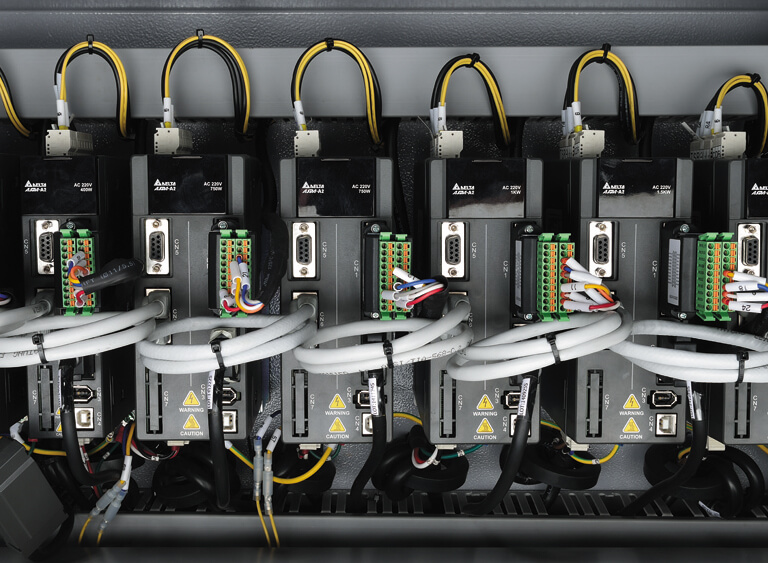

Network communication type servo control system

Application

Automobile / motorcycle brake & fuel tubing, water cooling pipes, air conditioning pipes, car seats, furniture, kitchenware, bathroom fittings, artwork architecture.

Specification

| Model Type | AUTO CNC-16-8 | |

|---|---|---|

| Max Tube OD. | Wire Carbon Steel | ∅10 mm |

| Wire Stainless Steel | ∅8 mm | |

| Low Carbon Steel | D12.7 x 3.0T | |

| Max Feed Length | 1200 mm,Length can be customized according to customer requirements. | |

| Max Bend Angle | ±180° | |

| Max Rotation Angle | ±360° | |

| Max Bend Radius | R60 mm | |

| Max Number of Bends | 200 | |

| Servo Number | 8-Axis | |

| Servo Motor Spec. Precision Speed | Sleeve Bend Angle | 1.0kW / ±0.05° / 700 RPM (700 RPM/minute) |

| Feeding | 1kW / ±0.05 mm / 550 mm/sec | |

| Rotation | 0.75kW / ±0.05° / 600°/sec | |

| Mandrel Bend | 1.5kW / ±0.05° / 350 RPM (350 RPM/minute) | |

| Shift | 0.4kW / ±0.05 mm / 500 mm/sec | |

| Collet Rotation | 0.75kW / ±0.05° / 600°/minute | |

| Bend Mold Up&Down | 0.4kW / ±0.05 mm (Lifting speed 350 mm/sec) | |

| Mandrel Bend Up&Down | 0.4kW / ±0.05 mm (Lifting speed 350 mm/sec) | |

| Collet System | Pneumatic Cylinder Drive | |

| CNC Controller | PC-based Controller | |

| Program Input | Input using touchscreen &hand –held control unit | |

| Memory Storage Capacity |

Can store a least 999.999 files using USB, or other commonly used devices. |

|

| Axis Control | Industry Servo Control Card | |

| Drive | Servo | |

| Electrical Capacity | Three-phase 380V 15KVA | |

| Size: L × W × H | 2400 x 1100 x 1500 mm | |

| Net Weight | 1700 kgs | |

| Air Compression Waste | 60 L/min, 0.6 MPa | |

| 8-axis servo motion powered by an AC servo motor | ||

* Our company continuously strive to improve our mechanical functions and quality. Any changes in our design shall not be notified.